Table of Contents

If you’ve ever turned the crank on a belt drive bike, you’ll have noticed that they don’t spin as freely as chain drive bikes. In other words, there is extra resistance in the drivetrain. How much resistance is this, and how does it compare to a chain drivetrain at varying power outputs? Let’s find out.

But first, a bit on belts…

Belts offer a few nice advantages over chains: a longer wear life (30,000km!), little to no drivetrain maintenance (no lube or degreaser), silent operation and a lower weight too. They work out particularly well for bike travel; it’s cool to see there are now over 40 touring bike manufacturers with belt drive bikes in their line up.

The main disadvantages of belts are that you need a belt-specific bike frame, the parts are hard to find in shops and there is a higher upfront cost. You can read the full pros/cons list HERE.

Friction Facts, a company acquired by CeramicSpeed in 2016, ran a very interesting test to determine the efficiency of a Gates belt drivetrain in comparison to a typical chain drivetrain. It turned out that, depending on the power output, both belts AND chains can be more efficient.

Huh???

(You can see the full test report HERE)

Preload Tension

The main source of friction in a chain drivetrain is the tension created by the rider pedalling. Belt drivetrains are a bit different because their main source of friction is simply the tension on the belt when it’s installed on a bike.

A high preload tension is necessary on belt drivetrains because, without it – the belt will skip on the cogs. A chain also requires a preload tension to ensure engagement with the cogs, but this preload is minimal in comparison. The weight of a hanging chain is usually enough.

Test Products

Chain Drivetrain:

– Two chain samples and two belt samples were tested.

– Chain 1 was a Shimano CN-7901 (Dura Ace 10sp). Chain 2 was a SRAM PC-1091R (Red 10sp).

– A 53T FSA front ring (107mm effective radius), and a 19T SRAM rear cog (78mm effective radius) were used.

Belt Drivetrain:

– Belts 1 and 2 were each Gates CDX belts (10mm wide and 125 tooth).

– A Gates 60T CDX front ring (106mm effective radius) and a Gates CDX 22T rear cog (79mm effective radius) were used.

Due to the different pitches of the belt (11mm) and the chain (12.7mm), different tooth-count rings and cogs were utilized in order to achieve similar effective ring and cog radii.

Test Method (Sorry, A Little Bit Technical)

In previous chain tests, the Friction Facts test rig was set to different ‘span tensions’ simulating different rider outputs. This allowed them to test different chains equally at different span tensions to find the frictional differences. Pretty simple.

Due to the high preload tension of a belt drivetrain, it’s impossible to run equal span tension tests between belts and chains, so Friction Facts instead decided to measure the frictional losses at different ‘total span tensions’.

Calculating Total Span Tension On A Belt Drivetrain:

When you pedal at 250 watts on a belt drive bike, the top span is subjected to 138.30lbs. This is made up of the 53.30lbs tension from the pedal input, plus the 85lbs of preload tension on the belt. The bottom span is subjected to 31.70lbs. This is the negative tension created by the 53.30lbs pedal input plus the 85lbs of preload (85lbs-53.30lbs). When adding together the top and bottom span tensions, the total span tension is 170lbs. Or more practically, we can just double the span tension on belt drivetrains to get the total.

Calculating Total Span Tension On A Chain Drivetrain:

When you pedal at 250 watts on a chain drive bike, the top span is subjected to 54.81lbs. This is made up of the 52.81lbs tension from rider output, plus the 2lbs of preload tension on the chain. The bottom span tension is subjected to 1lbs from the hanging weight of the chain. When summing the top and bottom span tensions, the total span tension is 55.81lbs on the chain drivetrain.

Comparing Frictional Losses Between Drivetrains:

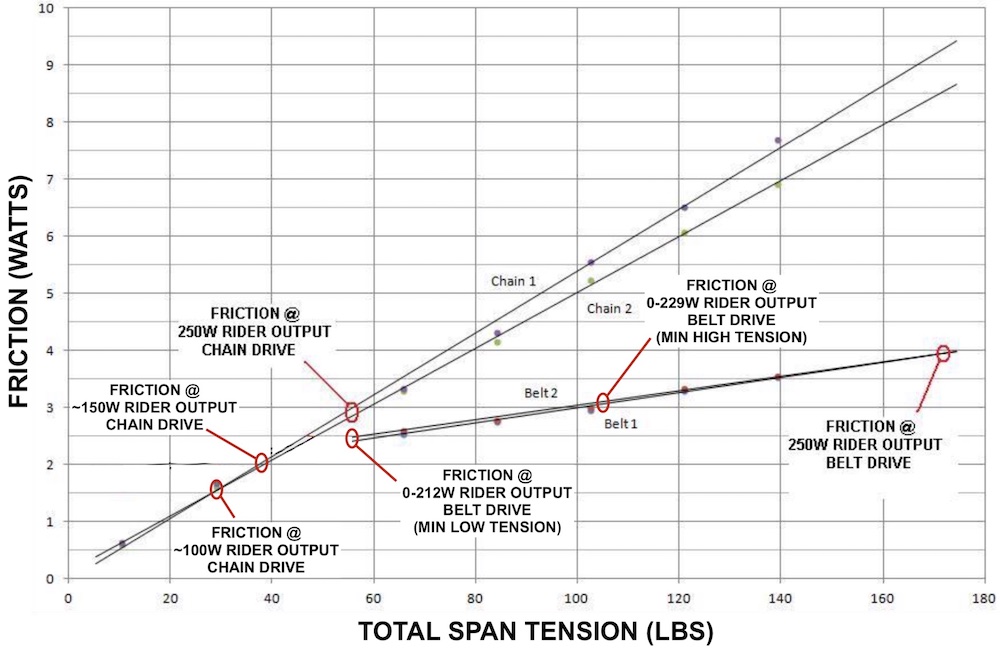

While the total span tensions work out to be different between drivetrain types, we can still compare the frictional losses by simply matching up the rider outputs on the graph. For example, look for 250 watts on both the belt and chain trend lines, and you can determine the frictional difference between the drivetrains.

More Test Details:

– The belts were subjected to one hour of run-in at 250W prior to testing.

– The chains were subjected to one hour of run-in at 250W prior to testing.

– Both chains were cleaned and re-lubed with basic light bearing oil.

– 95RPM cadence.

– Tension per span values are actual, not calculated, and measured at the span.

– The accuracy of the Full Tension Tester is +/- 0.02 watts.

– The system losses (the losses from the ceramic bearings used in the test equipment) were removed from the final results.

Results: Belt vs. Chain Friction

Frictional Losses at 100 watts:

Chain ~1.5 watts

Belt ~2.45 watts

Frictional Difference: ~1 watt (1% advantage to the chain)

Frictional Losses at 150 watts:

Chain ~2 watts

Belt ~2.45 watts

Frictional Difference: ~0.45 watt (0.3% advantage to the chain)

Frictional Loss at 208 watts:

Chain 2.43 watts

Belt ~2.45 watts

Frictional Difference: ~0.02 watt (0.00% advantage to the chain)

Note: The most convenient thing about this chain and belt testing is that the frictional losses are almost linear to rider output (you can see another test that demonstrates this HERE). The linearity allows us to easily calculate the frictional losses at different rates of power on the graphs – I have added the total span tension at 100 watts and 150 watts with the chain, and at 212 watts and 229 watts with the belt.

Analysis

It may be a little bit hard to interpret the data from the graph, so let me explain.

Due to the high belt preload tension causing 2.45 watts of resistance from the get-go, a chain will run more efficiently than a belt until you hit ~212 watts (when the resistance is equal). In practical terms, you can expect a chain drivetrain to hold an advantage of about 1-watt while pedalling very lightly, but this will drop to around a 0.45-watt at the average power output of a bike traveller.

If you combed through the original test report, you’ll have noticed Friction Facts drew most conclusions at a preload tension of 85lbs. This was the highest belt tension recommended by Gates back in 2010, but this is not very common these days as frame technology has improved.

The lowest belt tension that is currently recommended by Gates is just 28lbs (56lbs on the graph). This results in a 2.45-watt resistance when pedalling at rates of power between 0 and 212 watts.

A low belt tension like this is usually for smaller/lighter riders who have a smooth and steady pedalling style, however, bigger/heavier riders (like myself) can also use 28lbs or less with the right bike (my KOGA WorldTraveller frame has a very stiff rear frame triangle; see my belt setup including the low tension in this video HERE).

The highest belt tension that is currently recommended by Gates is 53lbs (106lbs on the graph). A high preload tension is needed for tall and powerful riders (or someone with a punchy or rough pedalling style). This results in a 3.1-watt resistance when pushing the pedals anywhere from 0 to 229 watts.

So if belts are more efficient at high power outputs, why don’t Olympic track riders use belt drivetrains?

1. They would need a higher preload tension than tested to keep the belt on the cog during peak power and torque. This would potentially result in higher resistance.

2. It’s harder to quickly swap gear ratios on a belt compared to chain drivetrains – something that track riders do often.

Important: Chain Lubricants

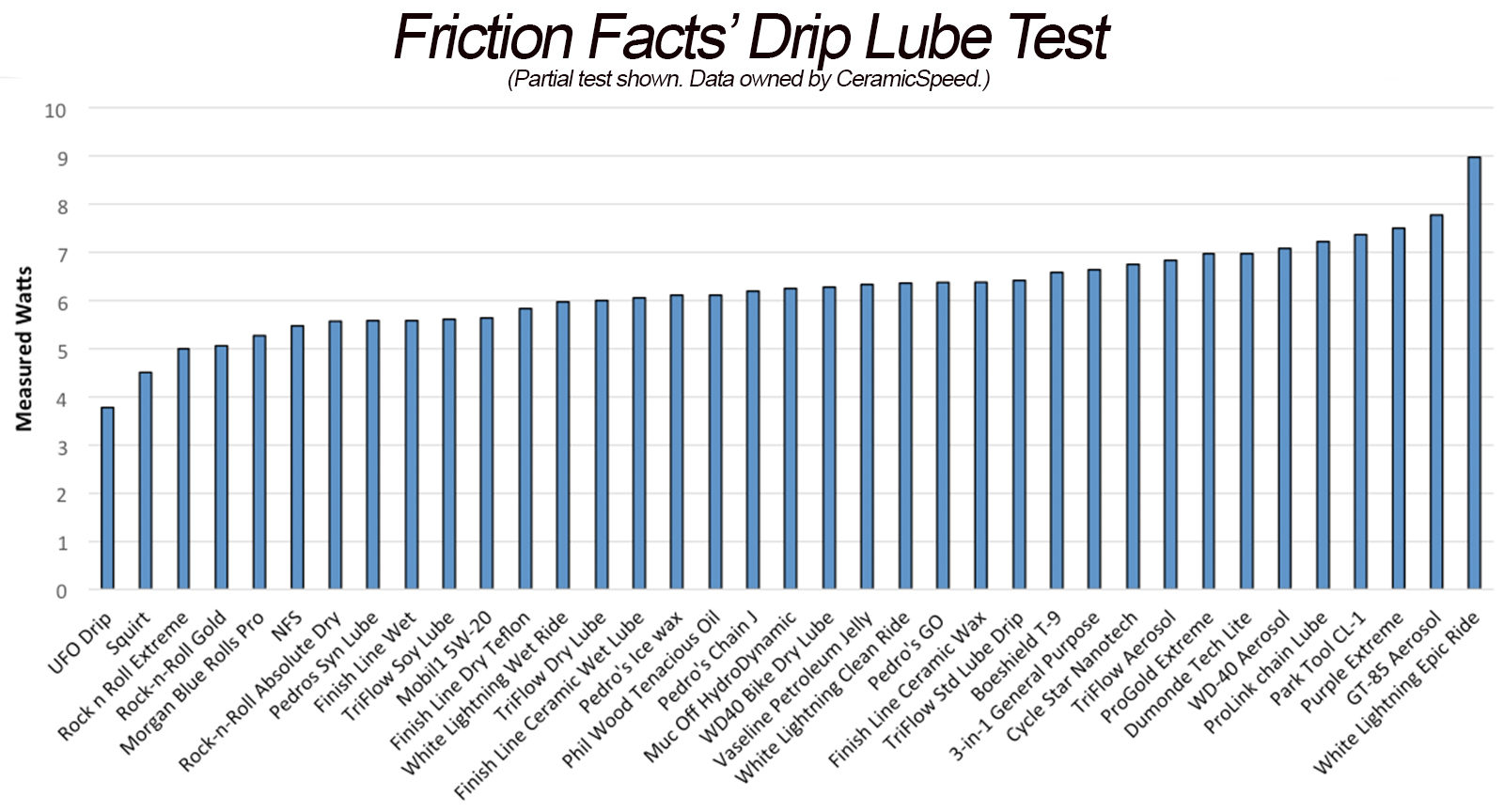

Friction Facts have also extensively tested the frictional losses of chain lubricants, and it turns out there is up to 5-watts difference between them! I’ve included this information as any advantages of a chain over a belt (low power outputs) can easily be negated by using a slow chain lubricant.

The take-home from this testing is that you should avoid common dry chain lubes if either durability or watts matter – wax and wet lubes are the fastest and least-wearing on your drivetrain. Keeping your chain as clean as possible is also vital to getting a respectable life and efficiency.

If you’re keen to know everything about chain lubes, check Dave Rome’s excellent article over at CyclingTips.

Summary

This lab test has determined that chains are between 0.3% and 1.0% more efficient at low power outputs (under 212 watts), while belts are more efficient at high power outputs (over 212 watts).

Things get a bit more muddied for the chain when we factor in different chain lubricant options. There are between 4-5 watts difference between chain lubricants alone – so pick your lube wisely!

Keep in mind these numbers were collected under perfect conditions, so mud and grit will play varying roles in efficiency under real-world conditions. It’s not hard to imagine a belt drivetrain having a significant advantage in muddy/gritty conditions, as it can shed debris very effectively.

With all things considered, the frictional differences between belts and chains are largely insignificant.

Check Out Derailleur Drivetrain Efficiency Testing HERE and Gearbox Testing HERE