Table of Contents

Krzysztof Wierzbicki is on a mission to find the degree to which the components of your bike can dampen vibrations.

Over the last few years, he has used his smartphone accelerometer to compare frame materials, seatposts, saddles, tyres, handlebars, stems and forks – you can see a list of all of his real-world vibration tests HERE.

Krzysztof’s testing has provided some interesting numbers, but he was keen to improve the accuracy of his data, so he built a treadmill that can control many more variables. He also invested in a professional accelerometer to take better measurements.

His new treadmill endeavour plans to provide the best information about the additional comfort on offer from different bike components.

The Effect of Tyre Pressure On Bike Comfort

The first experiment was a tyre pressure test.

Krzysztof’s personal experience is that lowering your tyre pressure will improve your comfort more than almost any other component. His real-world test on fast gravel roads and bumpy forest trails has found that the difference between 30 and 40psi is a 23.8 to 27.7% reduction in vibrations at the handlebar.

To put this into context, Krzysztof tested a Lauf suspension fork and found it reduced vibrations by only 1.3% when compared to the most compliant rigid carbon fork. Just a little bit too much tyre pressure in your front tyre and the vibration benefits of your fancy Lauf fork will have all but disappeared.

There is obviously a practical limit to reducing tyre pressure, and it will depend on your rider weight, whether you’re carrying luggage, your average speed and the types of surfaces you will be riding on.

The ideal tyre pressure won’t have your tyres squirming beneath you and steering unpredictably. It won’t result in too much rolling resistance. It won’t allow your rims to strike the ground when you hit hard-edge bumps, resulting in pinch-flats, or worse – totalled rims.

Ok, let’s look at the lab test.

Test Equipment

Krzysztof used his personal titanium gravel bike for this experiment.

His Enigma Escape is built using the following components:

– Open U-Turn carbon fork

– Coefficient Wave carbon handlebar

– 110mm alloy stem

– Spinergy GX front wheel

– WTB Byway 700C x 44mm front tyre (actual width of 42mm)

– Tubeless setup

Test Method

Krzysztof built a treadmill with varying bump heights ranging from 5mm to 18mm.

Given the short distance between each bump, 8kph (5mph) on the treadmill works out to be the equivalent of riding outside at between 16-24kph (10-15mph) on a bumpy road. And 16kph on the treadmill is the equivalent of 30kph+ on bumpy roads.

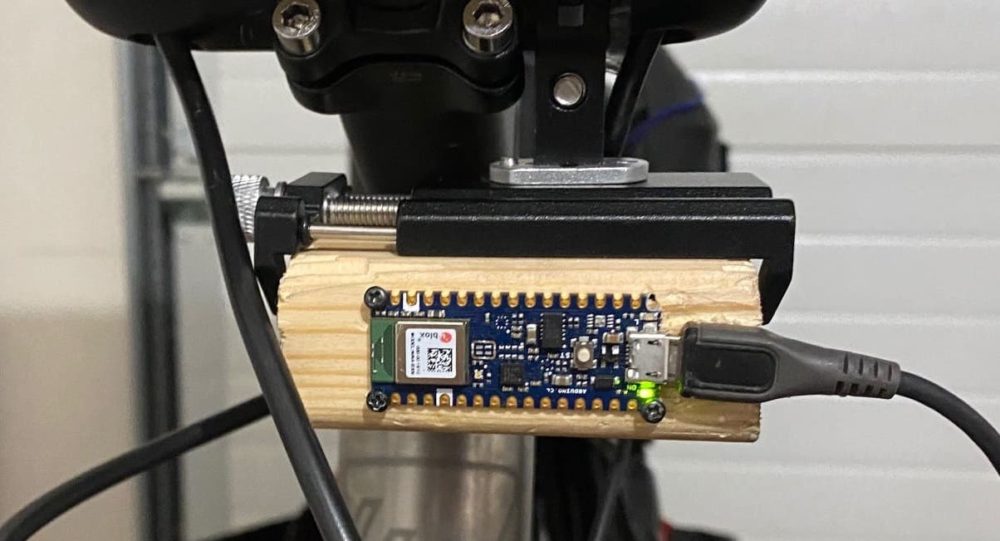

Vibrations were measured using an Arduino accelerometer with a high refresh rate. It was mounted on the handlebar next to the stem.

Krzysztof’s front wheel was placed on the treadmill and the bike was loaded with weight in a way that would simulate a rider of 75kg/165lb.

Krzysztof then took three 24-second vibration measurements at 5mph and 10mph and across tyre pressures from 25psi up to 50psi. The vibrations values (in m/s²) are the average of all three runs.

Results

Let’s start by calculating the reduction in vibrations for each 5psi drop.

“Fast Gravel Road” Test – Treadmill Speed of 16kph (10mph)

50psi – 4.1% fewer vibrations than 55psi

45psi – 6.1% fewer vibrations than 50psi

40psi – 6.8% fewer vibrations than 45psi

35psi – 12.2% fewer vibrations than 40psi

30psi – 8.5% fewer vibrations than 35psi

25psi – 9.9% fewer vibrations than 30psi

“Bumpy Forest Trail” Test – Treadmill speed of 8kph (5mph)

50psi – 3.5% fewer vibrations than 55psi

45psi – 4.7% fewer vibrations than 50psi

40psi – 5.9% fewer vibrations than 45psi

35psi – 8.9% fewer vibrations than 40psi

30psi – 7.3% fewer vibrations than 35psi

25psi – 10.3% fewer vibrations than 30psi

We can also use this data to see how higher speeds affect the level of vibrations at the handlebar (same pressures).

5mph vs 10mph at different tyre pressures:

25psi – 29.3% more vibrations at 10mph

30psi – 28.7% more vibrations at 10mph

35psi – 30.4% more vibrations at 10mph

40psi – 35.4% more vibrations at 10mph

45psi – 36.6% more vibrations at 10mph

50psi – 36.1% more vibrations at 10mph

55psi – 39.7% more vibrations at 10mph

Average: 33.7% more vibrations at 10mph

Analysis

Dropping from 40 to 30psi results in 20% fewer vibrations at the handlebar

When we use the Silca Pro Pressure Calculator, it suggests that ~30psi is appropriate for a Category 3 Gravel road (85kg rider+bike). Assuming someone of this weight has 40psi in their tyres, a 10psi reduction would net them 16.2% fewer vibrations at lower speeds and 20.7% fewer vibrations at higher speeds. That’s big!

There’s more comfort to gain at lower pressures

When we look at the 5psi interval differences, we can see that the biggest comfort gains are found between 25-40psi in this test – in fact, I’ve calculated that around two-thirds of the vibration reduction is found in this pressure range.

Comfort is more important at higher speeds

On average, there were 33.7% more vibrations at 10mph using the same tyre pressure. If we consider the time exposed to higher vibrations, a rider on fast, flat gravel roads has more comfort to gain by optimising their tyre pressure than someone who rides on slow, mountainous gravel roads.

The Case For Fatter Gravel Tyres

Simply put, larger volume tyres allow for lower tyres pressures – and lower tyre pressures allow for more vibration attenuation.

According to the Silca Pro Pressure Calculator, a 700c x 45mm front gravel tyre can be used with close to 10psi less pressure than a 700c x 38mm. This will likely result in more than 20% fewer vibrations at the handlebar (assuming a 75kg rider + 10kg bike on a Category 3 Gravel road).

This is a significant gain in comfort and is one of the reasons why wide tyre clearance should be:

1) A priority for gravel bike manufacturers

2) A feature that consumers who prioritise comfort understand well

Yes, tyre rolling resistance can be higher with a wider tyre on some surfaces, but the tyre tread and rubber compound are very large predictors of how well a tyre will roll.

To illustrate this, consider that a 37mm wide Maxxis Re-Fuse Gravel tyre has a similar rolling resistance to a 100mm wide Schwalbe Jumbo Jim fat bike tyre on the same surface.

Summary

If you’re keen to optimise the comfort of your bike, first you’ll want to make sure you’re getting the most out of your tyres by finding the appropriate pressure for the terrain you ride.

Many riders can likely decrease the vibrations on their bike by 10-20% just by dropping 5-10 psi.

As vibrations increase with speed, riders with higher average speeds have the most to gain from getting their pressures right. If you ride a lot of flatter gravel terrain, that might be you. The same riders will also benefit significantly from other comfort components like suspension seatposts and suspension stems.

You’ll want a tyre pressure that doesn’t feel too squirmy to ride, and that isn’t causing your tyres to bottom out on square-edge bumps. If you want to optimise the rolling resistance, the pressure will ideally be higher on smoother surfaces and lower on bumpier surfaces.

The Silca Pro Pressure Calculator is a great start for finding an appropriate pressure. That said, I’ve found it to spit out far too low pressures if your system weight is heavy (bike+gear+body) and you’re riding on rough surfaces. In this case, some ‘real world’ experimentation of your own will be required.