Table of Contents

It’s not worth settling for second best when it comes to rims as wheel failure can really put a damper on your tour. It is my experience that rims are one of the most important components of a touring bike. Even with the best quality wheel build, the nicest spokes and the most solid hubs… rims can and do fail due to heavy loads, braking and harsh terrain.

The strength of your rims will need to be matched to your body weight, estimated load and the type of terrain you’ll be riding on. If you’re a 50kg rider with a 10kg load, there is no way you need heavy duty touring rims. If you weigh 80kg and have a 40kg load – that’s another story.

In this resource, I discuss the key factors to a good touring rim and will make some recommendations for the best brands and models.

Understanding Rims

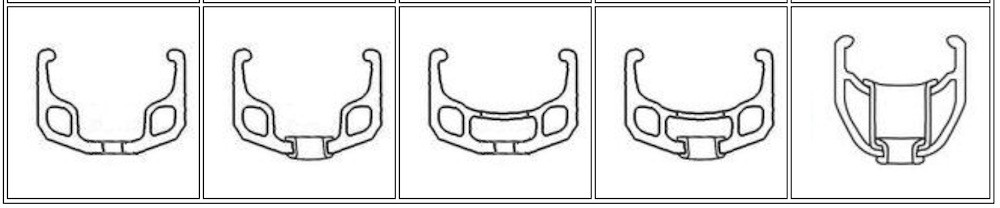

Almost all bicycle rims are made out of aluminium. They are constructed using semi-molten aluminium that is extruded through a mould in a certain profile, then manipulated into a hoop, and welded or pinned together. Aluminium rims can be as light as 300g and as heavy as 900g. Good touring rims are generally in the 550-800g range.

Aluminium superseded steel a few decades ago as it is lightweight, strong, rustproof and offers excellent braking in comparison. Carbon is becoming more prevalent on road and mountain bike wheels, although it’s currently quite cost-prohibitive. With carbon technology improving so rapidly I wouldn’t be surprised if carbon rims became commonplace on disc brake touring bikes within a decade.

Double Wall Rims

Rims can be single, double and even triple wall, although you’ll find all good touring rims in the double-wall variety. This simply refers to the number of aluminium layers to the rim.

Spoke Holes

Rims are available in multiple spoke hole configurations. The common touring setups include 32, 36, 40 and 48 holes. The advantage of more spokes is a decreased load across the hub, spokes and rims. I generally only recommend 40+ spokes for really heavy riders, people with heavy loads and tandems using 700C wheels with cassette hubs. Otherwise, you will likely roll happily with 32-36h rims, good quality spokes and a professional wheel build.

Eyelets

Eyelets are the aluminium sleeves that reinforce spoke holes. Not all rims are eyeletted, but some manufacturers use eyelets to build lighter rims without compromising on strength (for example, Ryde drops 70 grams off their rims when they use eyelets). Double-wall rims can come with single or double eyelets (socketed). Double eyelets evenly spread the spoke tension across both walls of the rim, allowing the rims to be lighter/stronger. They are available on the Ryde Sputnik, Mavic A719, DT TK540 and EXAL ML21/XL25 rims.

You’ll notice that many of the strongest rims on the list below achieve their strength without eyelets, instead, relying on extra-thick aluminium walls. It is therefore not a necessity to have touring rims with eyelets, although you can achieve a minor weight reduction if you do.

Rim Widths

Rims come in many different widths and should ideally be matched to your tyres.

19mm internal width: 25-62C (1.0-2.2″) tyres

22mm internal width: 32-62C (1.2-2.2″) tyres

25mm internal width: 37-62C (1.5-2.2″) tyres

Disc and Non-Disc

Some rims have been designed without a brake track for use with disc brakes. You can use a rim with a brake track on a disc brake bike, but not vice-versa.

Welded and Pinned

Once the rims are extruded and hooped, they are pinned together or joined with an arc weld. Most lightweight rims tend to be better when they’re welded, although with heavy-duty rims (500g+) I’ve found that the way a rim is joined contributes very little to the overall strength.

Brake Track Treatment

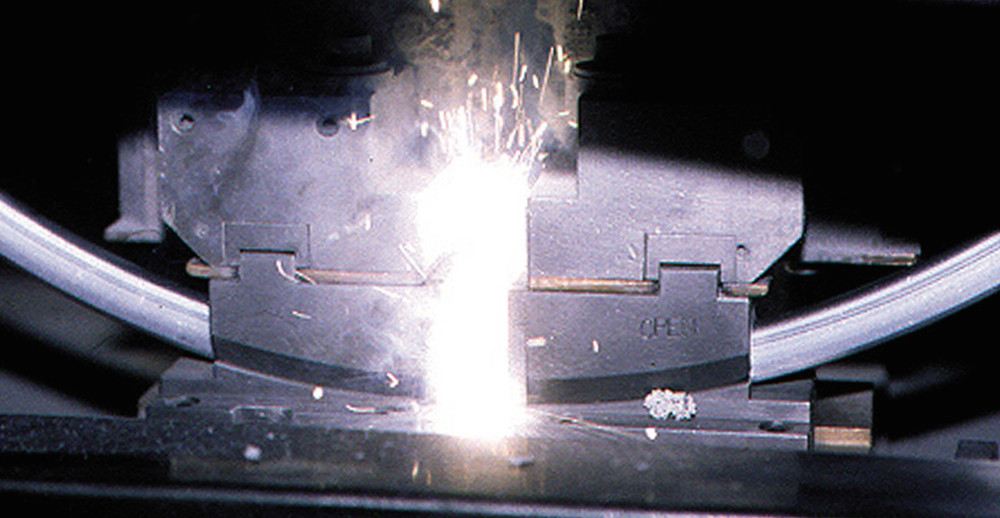

Some manufacturers offer special coatings on their brake track in order to increase rim longevity, improve braking performance and prevent failures. Ryde uses a Carbide Super Sonic (CSS) coating on all of their touring rims which is said to make them wear four times slower. The process includes blasting tungsten carbide into the braking surface at several times the speed of sound, making the surface extra hard and resilient to brake wear. Please note that you should ideally use CSS-specific brake pads with this braking surface, available from Koolstop, otherwise you’ll wear out more pads than necessary.

Rohloff-Specific 26″ Rims

As the shell diameter of a Rohloff hub is so large, it is best to use special rims that have their spoke holes drilled on specific angles, putting less stress on the hub shell. The Ryde Andra 30 and EXAL EX19 rims are the best to use for 26″ Rohloff wheels.

How Do Rims Fail?

Cracked Spoke Holes and Rim Centre

This is the most common form of rim failure on a touring bike. If your aluminium rim isn’t thick enough, you will find spokes pulling through your rim – even with eyelets. I’ve never seen or heard of this form of failure on Ryde Andra or Sputnik rims, but it is common amongst sub-500g rims.

Brake Track Splitting

A less common form of rim failure is along the brake track. This is said to be attributed to exceeding the maximum tyre pressure of the rim, in combination with a heavy load. If you’re really unlucky, it’ll simply be a manufacturing defect.

Brake Track Wear with Rim Brakes

Over time, rim brake pads wear away at the aluminium. The rate of wear depends on the conditions you’re riding in, how hilly it is and your braking habits. Most tourers experience over 20,000km of riding before needing to replace their rims. Ryde offers a carbide coating on their rims which is said to wear at a rate of 4x slower. If you’re going on a big trip, check their rims out.

Recommended Rim Manufacturers and Models

This is a list of the rims I endorse for heavy-loaded touring.

My favourite brand of touring rim, without doubt, is Ryde. I have no affiliation with this manufacturer but have found through 30,000km+ of tandem touring that nothing beats them on strength. It makes sense that they last – Ryde rims are often a couple of hundred grams heavier than other rim models. If you have four panniers and weigh a bit yourself, or you’re off on a big touring trip, those grams deliver a great piece of the mind.

26 Inch Rims

Ryde Andra 30 (Review HERE)

The strongest touring rim in the world

19mm Internal Width

32, 36h, 48h

735g

Ryde Sputnik

A slightly lighter version of the Andra which uses double eyelets

19mm Internal Width

32, 36h

670g

Ryde Andra 40

A wide Andra rim for 2.00″+ tyres

25mm Internal Width

32, 36h

750g

EXAL ML21

Hard to find outside Europe, solid performer

21mm Internal Width

32, 36h

600g

EXAL XL25

Hard to find outside Europe, designed for 2.00″+ tyres

25mm Internal Width

32, 36h

705g

Sun Rhyno Lite

A solid touring rim

22mm Internal Width

32, 36h

575g

Velocity Atlas Disc

A solid disc brake rim

20mm Internal Width

32, 36h

560g

Velocity Cliff Hanger

A wide touring rim for 2.00″+ tyres

25mm Internal Width

32, 36, 40, 48h

600g

Mavic XM719: NOT RECOMMENDED

Many tourers have experienced cracking on these rims

20mm Inner Rim Width

32, 36h

475g

27.5″/650B Rims

Velocity Atlas Disc

A solid disc brake rim

20mm Internal Width

32, 36h

590g

Velocity Cliff Hanger

A wide touring rim for 2.00″+ tyres

25mm Internal Width

32, 36, 40h

635g

700C Rims (29″)

Ryde Andra 30 (Review HERE)

The strongest touring rim in the world

19mm Internal Width

32, 36h

815g

Ryde Sputnik

A slightly lighter version of the Andra which uses double eyelets

19mm Internal Width

32, 36h

745g

Ryde Andra 40

A wide Andra rim for 2.00″+ tyres

25mm Internal Width

32, 36h

815g

EXAL ML21

Hard to find outside Europe, solid performer

21mm Internal Width

32, 36h

660g

EXAL XL25

Hard to find outside Europe, for 2.00″+ tyres

25mm Internal Width

32, 36h

770g

Velocity Atlas Disc

A solid disc brake rim

20mm Internal Width

32, 36, 40, 48h

620g

Velocity Cliff Hanger

A wide touring rim for 2.00″+ tyres

25mm Internal Width

32, 36, 40h, 48h

675g

Mavic A719

A common double eyelet touring rim found worldwide

20mm Internal Width

32h, 36h

565g

DT Swiss TK540

A common double eyelet touring rim found worldwide

20mm Internal Width

32, 36h

545g

Have You Used Any Other Rim That Can Be Recommend?

Velocity Dyad’s have held up real well under heavy loads Maine to Washington and on 200/300/400/600K rides. 240 pounds of me plus 3 person tent and panniers was quite a load.

I put Velocity Chukker on a Surly disk build . . Interested to know if anyone has thought of Chukker on a touring set up I am at 250 lbs plus gear and bike at 350 lbs

The Velocity Chukker rim is a very solid option. You should have minimal issues with those!

Great to hear – I’ve put many kilometres on Dyads myself.

I’ve been running Velocity Aeroheats on my Paratrooper for a few years now. Dics up front v-brake rear (a little wear showing) about to give them another workout for a few months.

Please help this guy out with advice, bicycle parts maybe a sponsorship from a wheel maker.

https://www.facebook.com/fatguyacrossamerica/

Nice article, as usual!

What do you think about the Ryde Andra 210 29″ for a disc brake bike Salsa Vaya?

It looks like a pretty solid rim, not too dissimilar from the Velocity Atlas Disc. I haven’t had any experience with it, but can imagine it would be strong enough for most touring.

Hey Alee, it’s a great post and very helpful for me. I’ve bought Surly Disc Trucker frame and at the moment, I am looking for a pair of rims. Here in Korea it’s not easy to get touring bike parts such as 36h/40h rims. As soon as I read your post I decided to buy one of the rims(Rigida Andra or Velocity Atlas Disc). Would you let me know any that I can order on the Internet? Oversea shipment should be available as I am living in Korea. Cheers

Hi Juntae. Sorry I missed this! Try SJS Cycles (UK) for a Rigida rim! Alee

Thank you for the review.

I strongly confirm Mavic XM719: is NOT RECOMMENDED

Got small problems with them on my 26 / 32 h / Rohloff . less than a year with 7’500 km !!! i am furious !

I am just 66 kg and ride with about 40 kg of materials

Hi Alee

I guess it doesn’t make much difference but Ryde have 28″ rather than 29″ listed.

http://www.ryde.nl/andra-30

Shane

Thanks – 700c, 28″ and 29″ are actually the same size, strangely!

I thought 700C Rims are 28″ but you write it is (29″)? anyway, the artical is amazing helpful! Thanks

700c, 28″ and 29″ are the same rims! The industry just measures tyres in slightly different ways to confuse us. :S

Rear wheel was having flat tyres, over a couple of days. As I use plugs instead of rim tape, i got a wet wipe and cleaned the rim and found a crack along the extrusion line. It was 5-10mm so to help till next shop I used a couple of layers of Tenacious Tape which worked. The crack had gotten bigger in that time.Had to make do with a Alex rim as it was the only 36 hole rim available at such short notice over the annual Japanese holiday period. Front still going strong. Now run discs front and rear, use pads really quickly with load and wet weather.

When did you buy them? I’ve got a pair on a tandem, so we weigh about 130 both of us together, + some 30kg luggage and we’ve ridden quite a bit already, without any problems.

I’ve been riding mine for several years now, built up on a Rohloff hub (36h) and have had no problems at all? I am using disc brakes too…

Just a side note about eyelets : the larger the hole drilled in the rim, the weaker the rim becomes. Eyelets are a way to reinforce what’s been weakened, but it’s still better not to weaken the rim too much. And Mavic 719 can be considered as lightweight rims, and not that appropriate for toaded tourism.

We have gone through a number of rims while tandem cycle touring over the decades. We carry about 20-25 pounds along with our 310 lbs of bodies on a 36 lb tandem. The high pressures we run, 120 psi in 28c tires and 105 psi in 32c tires puts a lot of stress on the rims. We use 32 hole front/36 hole rear rims for club rides and 36 hole front and rear for touring. We have had trouble with Velocity Fusion holding true and worst of all Velocity Deep V and FIR rims separating at their pinned joints. So we switched to welded/machined rims. Those with the smoothest joints, critical for braking with rim brakes, have been: Mavic A-719, HED Belgium Plus, H Plus Son Archetype polished (NOT their anodized), H Plus Son TB14, and DT-TK540 in that order from best to “worst”, with the worst still being better than a pinned joint rim. While I like the HED and H Plus Son Archetype, I have more faith in rims for touring with ferrules, so we use the Mavic A-719 touring.

A ferrule spreads the force around a wider area of the rim body, so is less likely to crack than a much smaller non ferrule hole spreading the force around the small diameter spoke nipple. I have had non ferrule rims stress crack, but not a ferruled rim.

I can’t find a store that sells Ryde Andra 30 in 700c in the US, well, or any where. . . Do they not make the rim in 700c anymore?

It’s still on the Ryde website, so not sure why shops don’t have stock of it. An alternative rim is the Sputnik (the eyeletted version of the Andra 30) which is available in 700c here: https://www.sjscycles.co.uk/rims-tape/32-rigida-sputnik-700c-622-touring-rim-black/

Hi Alee, Have you come across the DT Swiss 535 and 545 rims? They appear to be very solid rims built for e-bikes and trekking, and come in at less than a third the price of the TK 540. I’ve had no luck finding any reviews of them, but they would seem to be a very good option for the price. Would be keen to hear your opinion. Cheers

They’re obviously not as technologically advanced as the TK 540, but if they’re a third of the price, that’s great value for a rim that’s probably not far off the same strength.

I bot them on April 2015. Looking on various forums, I am not the only one who had problems with Mavic XM719. You wont have any problems before 5’000 km, but with Vbreaks, the rims get slimmer … I know it is under warranty but I do not want having any trouble anymore.

Luckily, my rims problems happen in Europe.

What would have happen in Iran or Burma, …

ah ah, make sens, i have Rohloff hub too with 32 holes BUT WITH V BRAKES

once the side get slimmer due to vbrakes, then you will have problems (starting about 6’000 km)

if you go to rolof website, they strongly recommend “Rigida/Ryde Andra 30 Rim

Available in a Rohloff-specific angled drilling to build a stronger wheel with Rohloff hubs ”

Those f…ing mavic rims where already mounted on my MTB Cycletech Papalagi.

The basterds, they just wanted to save money disregarding clients safety !

Supposed to be Swiss Quality, but actually made in China.

They are just bikes traders.

I strongly confirm that the (“supposed” Swiss ) MTB CYCLETECH is not professionnals.

I had many problems with their Geneva retailer JEAN BRUN (bike boutique ! not Walmart )

I reported to MTB CYCLETECH and asked for help. They just disregarded my distress.

SOLD IS SOLD.

No wonder, the founder of this company, Mr Butch Gaudi left the firm in 2013.

This is to say, if you are stuck in no where, forget about getting help !

if only i had known, I think I would have bot Koga

well, doing so, no wonder people build their own bike or buy at DECATHLON ( the best value for your money )

This message is not a prank !

Georges Thu ( my name ! not anonymous )

Hi Jas, I confirm, DT Swiss SPOKES are top quality !

I have now +10’000 km, no broken, still going strong .

although most of their stuff are made in china ( tawain is part of china, ah ah )

I normally ride with Oertlieb bag (very good quality) about 35 kg on forest/rough roads

this is NOT the case with mavic 719 rims, DE LA VRAIE MERDE !

Hey man, I know that this post is several months old but if you haven’t found a solution for a rim yet, any bike shop that has an account with the US Sapim dealer Provelo USA can order Ryde rims. There aren’t very many distributors but I know from my own shop experience that they can get that stuff. Hope that helps.

I’m about to buy a Bombtrack Beyond. The bike is “armed” with WTB “STS” double wall sleeved, TLC, i19, 32h. Does anybody have any expirence with those rims on a touring bike? Regards Piotr

They’re a pretty solid rim, Piotr. As to their durability, it really depends how much you’re loading your bike, and how rough the terrain is that you’ll be riding. For a big around the world trip with lots of gear, I’d probably suggest upgrading to a touring-specific rim (generally 100-300g heavier per rim). For a few tours here and there, you need not worry at all (especially if you’re loaded with two panniers or bikepacking bags).

I weigh 260 pounds what rims and tires do I need because the ones I got now look like I’m still riding on flat when they are full of air

You can pick many of the rims I’ve listed above. They’re as strong as it gets. As for tyres, you’ll want to go nice and wide to accomodate your weight. Check out the Schwalbe Marathon tyres.

140kg raider 2 heavy paniers in the back rack something in front rack plus trailer whit kid in the back. My spokes don’t like me.

I know the discussion is about which rims can withstand the most abuse on a touring bike, but the solution I have gravitated to was dispensing with overloading the bike altogether and simply loading up my Bob Yak or Yakima trailer that pulls behind very handily. I went through a lot of wheels and rims over the years, while going heavier and tougher and more spokes as I went along, but after switching to a trailer to haul all my stuff and noticing how light and responsive the bike was, with the weight offloaded, I became enamored with my trailer setup. I was even more amazed how well it tracks behind me in traffic and in tighter situations, that I thought it would never work. There are several companies that now make similar looking models, like the Bob Yak, and the one I recommend is the deluxe model with the built in shock absorber on the rear wheel. Another plus, is that you don’t have the problem of a very top-heavy bike, since now all the weight is next to the ground, making the bike much easier to maneuver when wheeling it around on rest stops and in and around places you stop on your trips.

This is definitely relevant information! I’ll hopefully be doing lots of trailer testing this year, including a big tour using a 10kg hybrid with a trailer which will actually weighs less in total than my touring bike.

I carry a passenger whom has poor health and tow a Bob. My bike is modified with a passenger seat. 26″ wheels and 1.5″ tyres and disk breaks My rear wheel has failed twice. Any specific advice on what wheel rim, spoke quantity and where to buy in Australia?

Hi,

I have a road bike, not quite suitable for loaded touring. Nevertheless, I do tours of up to 2 weeks with minimal gear (tent, sleeping bag), mostly 10kg on the back, about 4kg on the front, me(about 80 kg + 20L backpack). The wheels are starting to wear off, especially the rims and I can’t get much braking power anymore.

I would like to build a second wheelset on a pair of NOS Shimano Exage hubs I just bought (the reason for this choice is the 126 O.L.D. on my frame). There’s not much tyre clearance. I currently have Continental Gator HardShell 25x700C and I am not sure I can fit 28. The rim width can’t be 19 for sure, so the list of recommended tyres in the article doesn’t help in my case. My best option is a width of 15mm.

What rims do you recommend for the above setup?

Note: we have good and bad roads here. Unfortunately, I can’t avoid the bad roads (usually cracks, sometimes potholes), which can go on for tens of kilometers!

The Velocity Deep V would have to be the most bombproof rim available in a narrow width.

There are lots of options available to you. Call a shop that specialises in touring. For example: Cheeky Cycles, Omafiets in Sydney. Commuter Cycles, Abbotsford Cycles or St Kilda Cycles in Melbourne. Treadly in Adelaide.

I have toured extensively on 719s for 5 years. If they are built by a skilled builder they will be great. I have beaten mine to hell while loaded and they are in great shape.

I agree. My Mavic A719 700c rims have been flawless for the last few years of touring. But Ruzak may be referring to the Mavic XM719 26″ rims which are notoriously flimsy and should definitely be considered lightweight rims.

Alee, I have seen all the wheels you recommend for a heavier rider, but when I try to find wheels for sale on the internet, it is not easy? Many talk about selling you the rim? assuming this is for people that build wheels. I do not. I ride a Giant Cypress DX. My tire size is 700-38c. I weigh 264 lbs. What would you recommend. Josh

Velocity build complete wheels. Check out the Atlas Rim Brake Clydesdale Wheelset: http://www.velocityusa.com/product/wheels/clydesdale/atlas-rim-brake-clydesdale-wheelset

What do you think of this option?

http://www.spacycles.co.uk/products.php?show=3374

There’s not much information about the wheels, but it sounds like SPA Cycles have a bit of experience building tandem wheels (which need to be stronger than any other wheel).

I have a 27″ tourer and ride the Velocity Synergy rims. Have been very pleased with them.

They look like a fairly solid rim. Thanks for sharing!

Great article. Thanks for providing a ton of great content

Concur. The Mavic XM719 disc 26” 36h rims will crack. I ran them for several years without any issues. Then, as I was truing the wheels before a long tour, noticed a slight bulge in the sidewall on my rear rim. After removing the rim strip I saw a 9” crack down the middle. Luckily I had a replacement rim which I built up. Not a week later on a shake down ride noticed another bulge, where the sidewall split 6”. Unfortunately, I’m leaving on tour and had to use my last 719 rim and hope it survives the year long tour. Have not heard back from Mavic if they will warranty the rim.

I’m running Schwalbe Mondials 2.0 with around 55 psi. Total weight – bike, gear and rider is 280 lbs. Looking at the Mavic literiture I see the rims can’t handle much more air pressure.

The wife runs Sun Rhyno Lite and I ran Velocity Chukker several years back with no issues. Should have stayed with what works rather then trying to shave off a few grams.

I am in the process of assembling a bike for a 15 month expedition to South America. I thought the choice of the rim would be much simpler, but the difference between Andra 30 and Andra 40 is huge in my opinion.

I will ride a bike on 28 “wheels with disc brakes and Schwalbe Marathon EVO 28” x2.0 (50-622) tires. I will leave the option for for V-break. I prefer 36 spokes.

I will be very grateful for your help and I will share this knowledge on our travel forum (link to this comment). I have send similar question to RYDE, but I have to wait for response, and I am not sure if it will contain traveller practice.

I compared three rims from your offer and I can not decide which is the best:

ANDRA 30 – 19 mm internal width – https://www.ryde.nl/andra-30

1. Does the parameter ‘MAX. SYSTEM WEIGHT (KG)’ concern the weight of the entire bicycle with the cyclist and luggage? Or maybe for one wheel? I am sure that this parameter must be repeatedly exceeded, because it is on the verge of how much we weigh on a long trip. I have 85kg.

2. Is this the best choice for a 2.0 tire? Will it not be such a balloon with more defects? Perhaps I have to consider that temporarily I will put on another tire (wider or narrower) due to the lack of backup.

ANDRA 40 – 25 mm internal width – https://www.ryde.nl/andra-40

3. Is it not too wide and too heavy for my applications?

ANDRA 35 – 22 mm internal width – https://www.ryde.nl/andra-35

4. In my opinion, the rim is ideal for my use due to its width, but it is new and difficult to access.

Thank you very much for help. It will help me with my purchase and travel 😉

– I wouldn’t worry too much about system weight. The Andra series has proven itself on many ultra heavy touring tandems over the years.

– 2.0″ tyres are fine on 19mm rims. I’ve got them on my current Koga touring bike and Co-Motion touring tandem and the tyre profile is great.

– I recommend the Andra 30 because it’s the most proven touring rim. If you were using 2.25″+ tyres I’d suggest going to an Andra 35 or 40 to match the rim width to the tyre width.

– Wide rims are only really necessary for running low pressures off-road. When you’re carrying a load, you’ll want your pressure high to get the best mileage out of your tyres and to prevent pinch flats.

FYI…to most USA ride amateurs like me the KG KM stuff means not so much; like metrics applied to someone trying to reach a 6 to 7 foot high jump or 23 foot broad jump…not so Euro here in California. Otherwise good info on this site.

Hi, i ve seen ryde website and it states that the andra 40 is stronger than andra 30, what do you think?

Great post Alee! Been trying to figure out which rims to go with for my first tour and gotta go with the Andra 30s… Can these be used with disc brakes and are they compatible with tubeless tires?

I’ve had lots of experience with the Andra 30 and none with the Andra 40. It’s reasonable to suggest that it’s a stronger rim though, and I’d recommend it if you’re using tyres wider than 2.1″ (55C) because it will give a better tyre profile.

I try to accomodate with conversions as much as possible, but if there’s lots of numbers involved I tend to just run with metric to keep it easier to read.

thanks for the reply Alee, actually i usually use a 26 inch between 1,75 and 2,2, which one would you recomend? i found this thread looking for a bomb proof rim because ive had lots of trouble cracking them, especcialy double wall rims, not so much with single wall ones i never broke one, only spokes, i take long trips and carry usually around 40 kg of load on bad roads, and i enjoy climbing hard on the pedals so i find it frustrating to not be able of doing that with a weak wheel, thanks again !!

The Andra 30 will suit your needs, without doubt.

Hi, great review. I’d like to ask about DT Swiss 535. I’m looking for a good rim for my touring bike and it came as a good option.

Best regards

Looks like a pretty decent option for the price.

Thanks! Looking now, I realised it was asked before. Sorry for posing that question again.