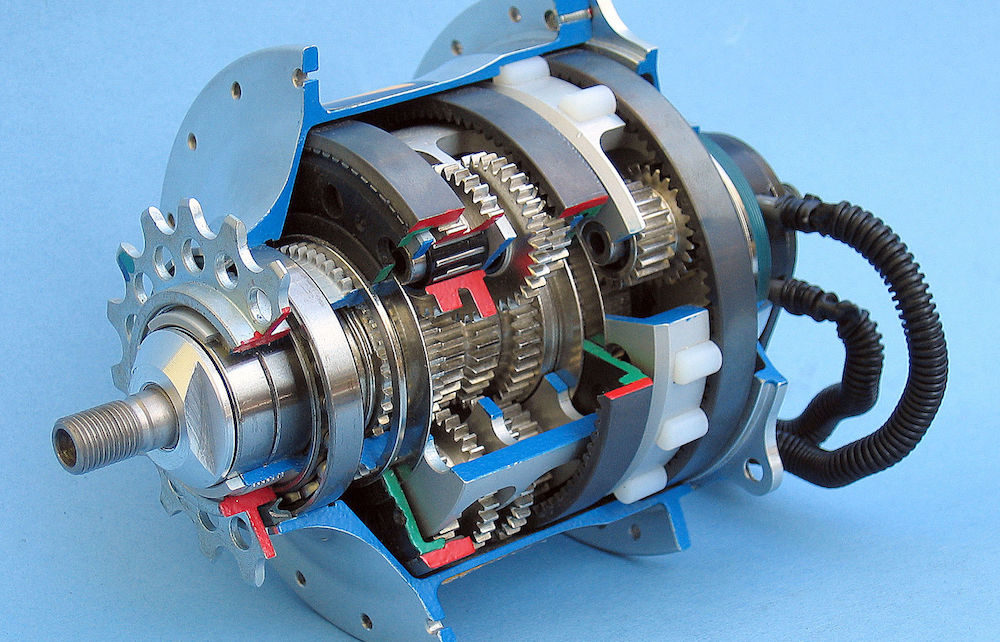

The Rohloff Speedhub 500/14 is an internally geared rear hub that has been servicing the demands of bike travellers for a few decades now. Inside the oversized hub shell are 14 gears which offer almost the same gear range as a regular drivetrain. These gears all sit inside an oil bath that’s sealed away from the elements. Gear shifting is completed via an easy-to-use twist shifter. As the chain does not have to move between sprockets, shifting works out to be quicker and more consistent than a regular drivetrain.

Rohloff hubs are perhaps a bit more common than you think. According to a survey of 327 cyclists that have completed bike trips over 10,000km in length, about 30% of all riders had Rohloff hubs fitted to their bikes.

I’ve personally been using Rohloff hubs on my bike adventures for about a decade. You will have seen them on my KOGA WorldTraveller, Surly LHT and Co-Motion tandem. I’ve found them to work great when the riding conditions are good and even better when they are not. I think I’d have a hard time switching back to a derailleur drivetrain for cross-continental rides after all these years.

Note: This piece was originally published in December 2011 – it’s had a makeover for 2018!

16 Reasons To Travel With A Rohloff Hub

1. The Sealed Gear Unit

Rohloff gears are hidden away, protected by the safe confines of a sealed aluminium hub shell. That makes a Rohloff hub extremely resilient against mud, grit, dust, snow and sand, and as a result, quite hard wearing.

2. The Sturdiness

Rohloff drivetrains have less parts susceptible to external damage. There are no exposed derailleurs, delicate hangers, brittle cassettes or spring-loaded shifters that can fail.

3. The Wide Gear Range

The 526% gear range provides plenty of gears to get up and over all kinds of terrain. With a Rohloff hub, you’ll be able to climb at 4km/h or motor along at 45km/h. I recommend setting the external gear ratio (chainring and cog) to something around 2:1 for mountainous terrain and between 2.5:1 to 3:1 for flatter terrain. The minimum ratio that Rohloff allow is 1.9:1 (eg. 32/17, 30,16 etc) – these ratios equate to a lower gear than almost any conventional drivetrain!

4. The Maintenance-Free Design (Almost)

Rohloff hubs should get you through a minimum of 100,000km riding before failure; many people have been known to cover far more. The only maintenance that you need to complete is an oil change every 5000km. This job is quick and easy, I can do it in about 10-15 minutes including waiting for the oil to drain from the hub.

5. The Minimal Drivetrain Cleaning Required

Getting the brushes between your cassette teeth, derailleur pulleys and chainrings is time-consuming and annoying. You can avoid almost all of this nuisance with a Rohloff drivetrain (ok, you still need to clean a singlespeed chain, but it’s much easier).

6. The Ability To Shift Your Gears Without Pedalling

You can change gears without pedalling – a particularly handy feature for a loaded touring bike. For example, you can pick your gear before you take off at the traffic lights, or select the appropriate gear for starting on an incline.

7. The Ability To Change Many Gears At Once

You can change multiple gears in one go with a Rohloff hub; the limitation is the amount of movement you have in your wrist. I can change about eight gears at once, of which I’ve had to do under rapid deceleration! That’s sandy roads for you…

8. The Equally Spaced Gear Ratios

There is a constant 13.6% ratio change between every gear, making gear changes very predictable. Other internally geared hubs offer inconsistent ratio changes to compensate for their lack of gear range.

9. The Instant Gear Changes With No Chance Of Gear Skipping

As soon as you change the gear at the shifter, the hub is instantly engaged in the next gear and ready to go – there’s no dilly-dallying around here! With the gearbox being ‘indexed’, there’s no chance of a gear slipping either.

10. The Straight Chain Line

The chain line on a Rohloff drivetrain is perfectly straight, resulting in less chain wear. This equates to a longer chain life; I know people who’ve toured well over 20,000km with a single chain.

11. The Zero-Dish Wheel Build

Rohloff hub flanges are both the same height and are spaced equally from the frame on both sides. This results in even tension across every spoke which, in turn, build a stronger wheel.

12. The Efficiency

According to independent testing, Rohloff hubs are just as efficient as a derailleur drivetrain at transferring the power from your pedals to your rear wheel (~95% efficiency). In the mud, they would presumedly be even more efficient!

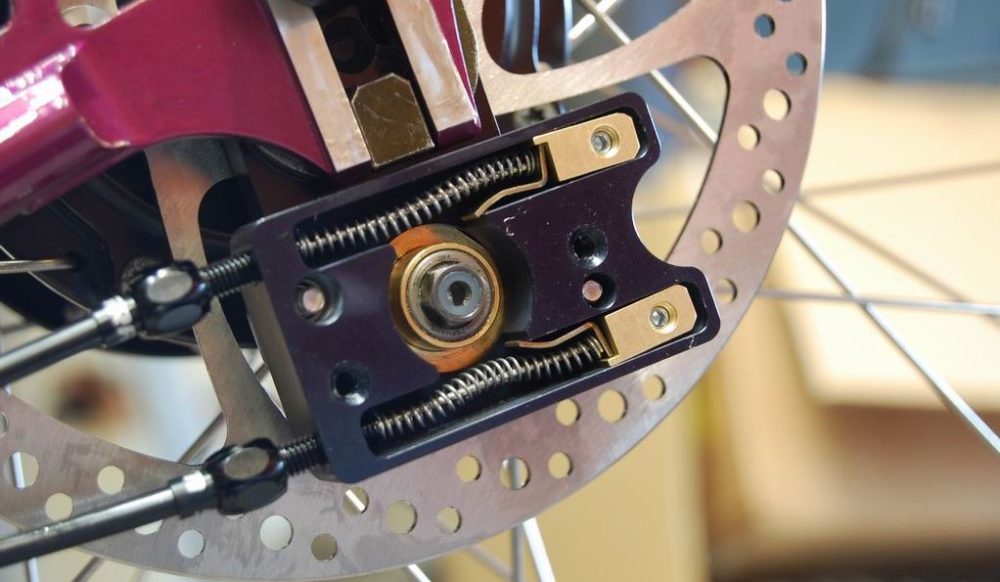

13. The Simple Shifter

Rohloff hubs use a dual cable system which requires both cables to either be pushing or pulling. Unlike a conventional trigger shifter, there are no springs or moving parts, eliminating it from potential failure. Once a Rohloff shifter is set up, the cables never have to be adjusted as the gear indexing occurs inside the hub.

14. The Shorter Spokes

Rohloff hubs have a bigger shell, resulting in shorter spokes and therefore a stronger wheel for any given wheel size. Wheel strength is key for touring, as the rear wheel often takes such a heavy beating. You can read how to build a strong Rohloff wheel in my resource HERE.

15. The Carbon Belt Drive Compatability

Belt drivetrains are fantastic! Belts are silent, belts are lightweight and belts are clean (no lube/degreaser required). I normally get over 30,000km out of a belt before needing to replace it too – try getting that out of a chain! You do need to have a belt compatible frame to run this option; I’ve got a big list of them HERE. You can also read all the nitty-gritty on belt drivetrains in my carbon belt drive resource.

16. The Chain Can’t Fall Off

Given the singlespeed drivetrain, you should never experience dropped chains, chain skip or chain slap on your chainstay. All the benefits of singlespeed life but with 14 gears!

9 Reasons To Not Tour With A Rohloff Hub

1. The Noise

I think the biggest downside to the Rohloff hub is the noise that occurs in gears 1 through to 7, but especially in that 7th gear. I’ve gotten used to the light whir of these gears over the years, but I sometimes find myself avoiding gear 7 so that I can enjoy the peaceful surrounds. Rohloff hubs are perfectly quiet from gear 8 through to gear 14.

2. The Price

There’s no beating around the bush here – Rohloff hubs are expensive. Expect to pay US $1600 or 1100€ just for the hub and shifter (complete bikes start at 2500€). You’ll need to factor in the cost of a new wheel build too. I’ve always justified the cost of buying a Rohloff hub knowing I won’t need to replace anywhere near as many cassettes/chains/chainrings. The sheer number of kilometres I do (probably) makes them cheaper in the long run.

3. The Need To Send Rohloff Hubs In For Repair

Should the internal gearbox fail or you crack the Rohloff hubs outer shell, you will need to send it off to a service centre to get fixed. Provided your hub is under warranty, Rohloff normally covers the shipping anywhere in the world. This may be a deterrent for you if you’re travelling to remote locations, but in my experience, both these things are quite unlikely to happen. The only major problem I’ve had over the last 10 years was a cracked hub flange (which was likely my fault, see no.4).

4. The Need To Maintain Even Spoke Tension

When your spokes become uneven throughout the wheel, it puts a lot of stress on the tall aluminium hub flanges of a Rohloff hub. It’s important to check your spoke tension periodically, and avoid cycling with broken spokes. The result of riding with broken spokes and uneven tension is the chance of the flange breaking (see no.3).

5. The Need For Angle Drilled Rims (26″ Only)

With the short spokes of a Rohloff 26″ wheel, it’s best to use a rim from Ryde with angled spoke holes. This reduces the stress on the spoke heads at the rim and ultimately stops any spokes from breaking. You can read more about this HERE.

6. The Spare Parts Need To Be Shipped In

Need a new cog or some hub oil? You can’t just go to any bike shop to pick up. Most of the time I have to plan ahead of time and order my replacement parts online. Hot tip: I’ve found that road inner gear cables matched to standard outer brake cables work fine as replacements.

7. The Fact You Can’t Shift Under Load

While it’s not best practice to shift under load on any drivetrain, a derailleur has a much higher tolerance for it. There is a technique to shifting on a Rohloff hub where you back off on your power for a split second to make the shift. This takes a bit of time to master but becomes second nature in no time.

8. The Twist Shifter

The twist shifter divides people. The good news is that there are lots of aftermarket options as well as hacks for drop-bar bikes (check out the Rohbox). If you use flat bars you can choose aftermarket trigger shifters too. After getting used to the twist shifter, I now prefer it as I can dump up to 8 gears at a time.

9. The Extra Weight

Rohloff hubs are heavier than the equivalent high-end derailleur drivetrains. But it might not be as much as you think. I’ve calculated that a Rohloff drivetrain using chain drive adds 500 grams when compared to a 2x Shimano SLX drivetrain, and about 900 grams when compared to a 1x SRAM GX Eagle drivetrain. You can see the weight differences in detail HERE.

Other Rohloff Resources On CyclingAbout

23 Ways to Run Rohloff Shifters on Road Handlebars

2016 Rohloff Thru-Axle Rear Hub and Upgrades

Complete List of Gates Belt Drive Touring Bike Manufacturers

Gebla Rohbox: Combine Road or Mountain Shifters With Rohloff Hubs

How to Build a Strong Rohloff Wheel

Rohloff Frame Options For Custom Rohloff Builds

Rohloff Hub Oil Change Instructions and Service How-to

The Bpod PSH’R Trigger Brings Hydraulic Shifting To Your Rohloff Hub

Understanding the Different Types of Rohloff Hub

What’s The Difference In Speed Between Gearbox Systems? Rohloff, Pinion, Shimano

I think I counted 56. Points please!

Love my Rohloff equipped Thorn Nomad Mk II. I know I could buy 10 good quality Shimano chainsets for the same price, but who wants to spend the time cleaning, adjusting and ultimately always replacing them? The Rohloff does it all, it does it simply and efficiently. Install it and forget it (within reason!).

Paul

cycletothesea.blogspot.com

Points awarded! Great choice of bike too, Paul!

Good article. However, two of your points:

Point 12) Rohloffs are not as efficient as well-maintained derailleur drive trains, despite what the good Heir Rohloff claims. If you compare the forward spinning of a rohloff rear wheel compared to that of a dérailleur, the rohloff wheel slows down quicker. If you backward spin the cranks on a rohloff wheel, they slow quicker and have more friction than those on a dérailleur, even allowing for the dérailleur chain tensioner. These losses are fixed losses and mainly due to oil seals. Furthermore, internal gears have meshing losses in addition to the sprocket/chain/chainring losses of both gear types.

Point 2) Yes they are sturdy, but mine lost gears 1-7 through slippage 3/4 of the way through a tour of Europe. At least with a dérailleur problem I could have fixed it by the road or, at worst, at the next local bike shop

The Rohloff is a great hub gear – but it’s not magic…

Thanks for the response!

We have not done any specific testing on the hubs efficiency, and we feel that Rohloff’s numbers could potentially be skewed when they say their drivetrains are just as efficient. I agree that more resistance is felt through the drivetrain when the wheel is moving forward and the pedals stationary due to the Rohloffs hub seals.

The main statement that was made on point 12 was that the Rohloff is really efficient in its own right, especially stacked up against other internal geared hubs and is pretty damn close to a conventional drivetrain. I definitely do not notice any extra resistance on a loaded touring bike or mountain bike!

It sounds like you’ve had a bit of bad luck on the hub, I hope Rohloff helped you out suitably. We will be writing about how our hubs change over the next two years, and will make sure everybody knows about any issues we have with them!

The key words are “well-maintained derailleur”. Sure, when they’re clean, lubed and perfectly indexed, they’re ideal. But on a long tour through mud and dust and heavy leverage they don’t stay perfect and require a fair bit of maintenance to keep running true. My own reasons for picking a Rohloff are partly due to it being enclosed and less prone to muck and knocks. I can’t say I’ve noticed any difference in handling a fully-loaded Rohloff bike compared to a fully-loaded derailleur equipped bik and the ability to change gear while stationary is a noticeable bonus.

Thanks. As Hub gears go, the Rohloff is indeed a Meisterwerk of engineering. My point was simply that, as a hub gear, it can never be as efficient as a direct drive system (eg a dérailleur).

My hub was fixed by Rohloff and has worked well since. The only thing Rohloff found wrong was that there appeared to be a small piece of Loctite loose within the hub mechanism.

Given that I have only ever performed the recommended oil changes since new, I’m not sure where this Loctite came from…

As my last sentence suggested, I think the Rohloff is great. But it’s not as efficient as a direct drive as some folk keep claiming, and, although unlikely, it can go wrong. When it does it’s not easy to fix yourself!!!

Cheers

A muddy drive-train on any bike, hub or dérailleur, is going to reduce efficiency by increasing chain losses due to increased friction in the chain bushes and where the chain meets the sprocket and chainring teeth faces. The differences are:

1) because Rohloff sprockets don’t de-rail, the sprocket teeth faces are larger, resulting in less chain-slipping in muddy conditions

2) the gear change mechanism on a Rohloff is internal, therefore gears change regardless of a muddy drive-train. On a dérailleur, gear changing will become non-operational in mud

As a Rohloff owner I am fully aware of the advantages of the Rohloff hub, particularly the longer life drive-train, and would always use one in preference on muddy rides.

But the claim that the Rohloff is more efficient, in terms of energy out/energy in doesn’t stack up when compared with a direct drive system. We should be careful not to claim that.

Cheers

One reason not to use Rohloff: noise. NoISe. NOISE!

Sure you can change gears while stationary on a derailleur bike: stay clipped into a pedal with one foot, apply front brake, lift rear wheel, and pedal into the gear that you want. It’s easy and works well.

True, but it gets a bit tougher with fully loaded panniers sitting on the rear rack.

I have heard fron Rohloff riders that there is a slight loss of energy, The peace of mind of having a near eternal almost maintenance-free gear hub comes at a cost.

The fact that you need to take less tools and spares is also a clear plus but I wonder how would you rate the Alfine 11, apparently it has the same gear range with only 3 gears less, but many also say that some gears in the Rohloff may be redundant.

Costing around 450 euros, the Alfine eleven gives almost the same at less than half price. It has been just a few years in the market so there is no way to attest if its durability is a match for the Rohloff’s, but given the price difference I thinhk it is worth giving it a try.

I too have a Rohloff Equipped Thorn Nomad MKII……… Once run in ? The hubs noise is no worse than a derailleur system in my honest opinion……. Changing gear at a stand still is awesome ! I use mine for everything ! Not a fast bike but a superbly built and absolutely bullet proof !

I agree with you on all counts, Ian!

Having spent a lot of time on Alfine hubs before the Rohloffs, the biggest difference for me is the way that the hubs feel to pedal. There is a spongy, springy feel that feeds back to the pedals (from the hub) when you apply force on an Alfine drivetrain. In comparison, the Rohloff is as direct with the power you put down as a conventional drivetrain (or at least, that’s how it feels).

There is no doubt an Alfine is better value for money, but given the kilometres that tourers travel, I’m sure many can justify the cost.

I’m trying to get a weight comparison between a rolloff setup + singlespeed vs a classical 3 chain rings + derailleur (say XT).

Anyone?

Hi Enrique. My calculations come to about 800g difference from a Rohloff set up to a Shimano XT drivetrain. The number breakdown is in my Pinion article: https://www.cyclingabout.com/index.php/2012/09/pinion-18s-gearbox-the-future-for-bike-touring/

Thank you for the clue. Very useful article, indeed.

Regarding your point about being as efficient as a derailleur drivetrain is true under certain conditions. One of them being if you are running in the direct drive gear #11 and you have a direct chain drive from chainring to sprocket without any chain tensioners or snubbers. In this scenario, the Rohloff hub is more efficient than any derailleur drivetrain in any gear. I use my Rohloff a little different than most I think. It is setup on a road bike frame with horizontal dropouts. I do use all gears on most rides but I have sized my chainring so that I spend about 70% of my rides in gear 11.

Something interesting I have noticed in all these discussions about Rohloff efficiency; many of those commenting associate a little noise with drag. If that were true, then there is always drag with a derailleur drivetrain when pedaling because the derailleur is always making noise when the chain is running thru it. At least the Rohloff only makes some noise in the bottom 7 gears.

Also, I want clarify something; there are no redundant gears in a Rohloff. Each gear is about 13.7% less or greater than the one on either side of it. Many derailleur drivetrains do have redundant gears if there are derailleurs on both front and back.

I’m not a Rohloff idealogue, I just want to mention some things that others may not have experience with or knowledge of with Rohloffs.

Rohloff does not have redundant gears. It’s 14 evenly stepped gears. The minimum chainring:cog ratio is ~2.35 for Rohloff and 1.9 for Alfine (back in 2012). However, if Rohloff gear ratios are 1 thru 14, the an Alfine 11 would cover the following Rohloff gear ratios: 4,6,7,8,9,10,11,12,13,14,15.

The Rohloff has 3 lower ratios (think granny gear) the Alfine doesn’t cover, Alfine has one higher ratio beyond Rohloff’s 14.

Thanks for sharing such useful information in your blog. Thanks for Sharing.

Rohloff Speed Hub

I’ve got Rohloff on my 2 recumbents and now about to replace my Campag with one too as they are just so forgiving. I made a short 3 day canal-side UK tour with a ‘detail-focused’ I.T. friend who rode a new carbon mountain bike equipped with deralieur kit. I rode a Recumbent Streetmachine with Roholff drive train – all steel and many times the weight. MAny times we had to stop and dis-entangle his deralieur from extensive flora together with temporarily loosing access to some of his gears aleviated with beer. The noise factor with the Rohloff varied depending on the gear being used but was not significantly different from the deralieur. It was this sojourn that encouraged me to replace my upright gears with Rohloff too. I will look at a front mech to work with it too and offer that extended range for hill climbing. Not susre how possible this will be though.

Cheers.

I have a Rohloff 14 speed coupled with a 38/48 front crank, giving me 28 speeds on my long wheel base recumbent bike that I principally use for touring,(4 panniers, + rear rack bag). It’s geared to 15 gear inches low gear, 102 gear inches high gear. It is a nice gear assembly and makes shifting on the fly very quick, especially in traffic. It adds additional weight (0.5 kg) on a already heavy bike (25 kg bike unloaded) so that hill climbing has become essentially zero (walk it up), it would be better for a mountain bike,crossover bike or even a tandem. I may get around to doing this switch to one of my other bikes.

I did have a problem with breaking spokes using the Rohloff until i purchased a specially offset hole rim made in England for Rohloff’s that experienced spoke breakage a lot, since than no spoke breakage.

I want a great touring bike (money no object) with Rohloff & Gates Belt Drive….Can anyone direct me? I’m going across the U.S. this Summer and I need some help. I’ve seen Spot bikes and I know the Surly Ogre can take the Rohloff…but I don’t want to cut into the seat stays. Someone…anyone?

You’re going to want to get in contact with Co-Motion Cycles! I use their Rohloff/Belt tandem and it’s amazing.

Let me add a 16th reason.

When the chain falls off your derailleur or cog or sprocket you have to stop and fool with it. I did that once, unbeknownst to me, right next to a baby black bear. I simultaneously saw the cub and heard the roar. Mother bears are notorious for taking a dim view of anyone getting too close to their cubs. Being the brave strong man I am, I ran like a little bitch.

Now I tour with a Rohloff.

LoL!